Multiwall Cement Paper Valve Sacks Machine with High Quality

Basic Info

Model No.: ZT9802S+HD4916B

Product Description

Model NO.: ZT9802S+HD4916B

Type: Prestretching Wrapping Machine

Application: Cement Packing, Carbon Packing, or Other

Inclusion Degree: Fully Wrapped Winding Machine

Tube Width: 420_620(Mm)

Bag Length: 520_880(Mm)

Design Speed: 80_130PCS/Min

Specification: CE

HS Code: 8441200000

Packaging Type: Bag

Driven Type: Electric

Automatic Grade: Automatic

Tube Length: 670_1035(Mm)

Max. Speed: 150PCS/Min

Bag Width: 420_620(Mm)

Trademark: Tecon

Origin: Guangdong Foshan

SPECIFICATION OF

Chemical Paper Bag Making Machine

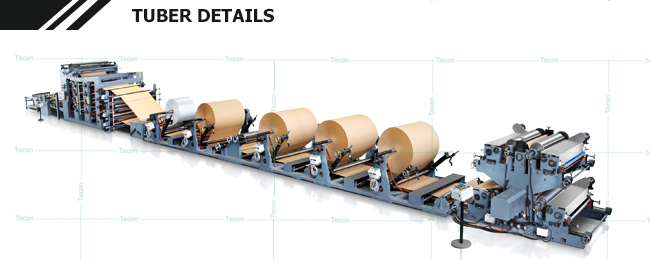

ZT9804S tuber machine with servo system

The ZT9804S Tuber Machine, which is developed by our company on the basis of ZT9804 standard tuber machine, is added a servo control component on each of the four key procsses (printing, perforation, gluing and separation), to form a closed-loop servo control system by the PLC, servo control module, the main frequency traction motor, servo motor group,encoder, color components to ensure that the cutting position of each printing bags matches the color patch of the tube. Through the touch screen, it is easy and visualized to adjust the specification of tube.

When it is on-line printing, ZT01 print unit prints precisely and neatly, and it only needs to replace print roller and its Gear. Through adjustment of thorn-ranked knife position, ZT07 separation machine can cut both the ladder-cutting and straight-cutting tubes. Other related adjustments are operated on touch screen, saving of labor and time .

When it is not on-line printing, besides the above characteristics, when requires more high-precision printing quality, it can complete printing by the using of other printing equipments, producing tubes in ZT9802S Tuber machine, expanding the specification of tubes of ZT9804S(400mm-2000mm). Need not to change any specification wheel, all adjustments are operated on the touch screen.

ZT9804S is applicable to producing variety of paper bags, especially when in producing starch paper bags, tea bags, chemical bags and so on, which need frequent specification changing and high-precision printing quality, it can fully play its unique advantages.

| Type | ZT9804S |

| speed | 120 tubes/min |

| Tube Width | 380~620mm |

| Tube length | 400-1400mm |

| Specification gear | 51~80 teeth(M=4) |

| Type of cutting | Step cut&Flat cut |

| Number of ply | 2~4paper+ 1 PP/PE |

| Diameter of print roller | Ø196~ø312 mm |

| Printing width | 1300 mm(MAX) |

| Paper reel diameter | Max. 1, 300 mm |

| Paper reel width | 860--1260mm |

| Main drive motor | 47KW |

| Servo system | YES |

| Machine size | 35.32.42.7(M) |

| Machine weight | N 32(T) |

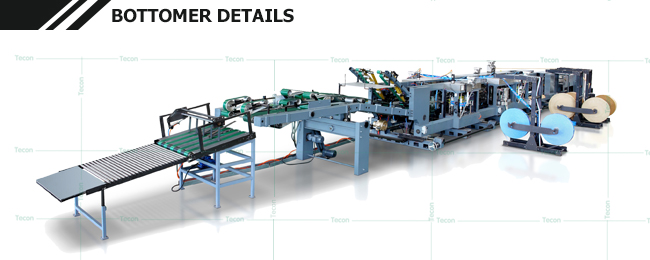

HD4916BD Bottomer Machine with reinforcement unit

The HD4916BD BOTTOMER machine, bottom-pasted and valve-making are completed on it. By using rotary vacuum feeding unit, this machine can run at high production speed to meet volume requirement. Mahicne is fully automatic in pasting valve scrip and reinforcement sheet to the bags, including guiding, cutting and gluing, which runs synchronously with the whole line, ensuring pasting the valve scrip on the correct position.

| Type | HD4916BD |

| Speed | MAX 100/140 bags/minute |

| Tube Width | 380~600 mm |

| Bottom Width | 80~160 mm |

| Valve Sheet Length Width | (100-300)(120-240)adjustable |

| Bag Length | 520~880 mm |

| Bottom Center Distance | 420~780 mm |

| Number of ply | 2~4paper+1 PP/PE |

| Strength sheet unit | YES |

| Strength sheet length*width | (300~600)(80~160) |

| Main Drive Motor | 40KW |

| Machine size | 23/281.81.8(M) |

| Machine weight | N34(T) |

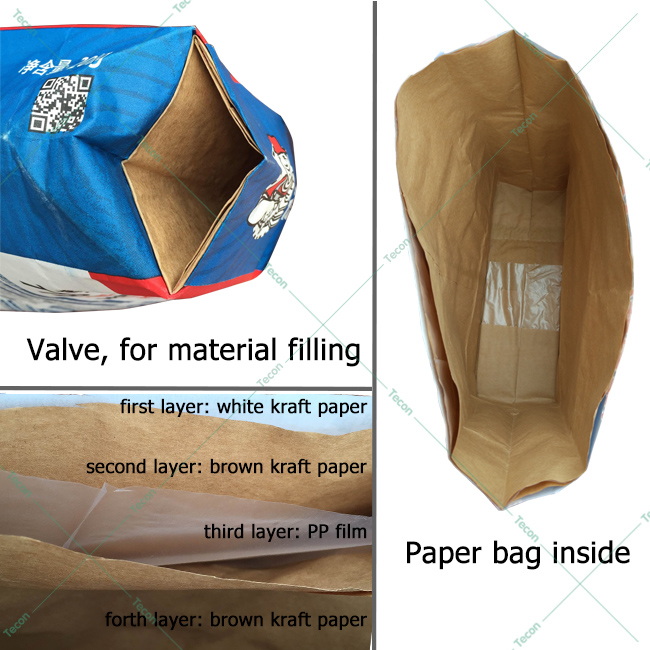

Cement Paper Bag Details

Size: normally 62cm x 50cm x 10cm (Length x Width x Bottom Width) for 50kg cement bag.

Loading Capacity: 25kg, 40kg, 42kg, 50kg

Ply of Paper: 2 ply of 90g paper / 3 ply of 75g paper

Reinforcement: optional

Perforation: optional

Cutting: step cut / flat cut

Recommended Machine: ZT9804 TUBER & HD4913 BOTTOMER

Chemical Paper Bag Details

Size: normally 39cm x 37.5cm x 10cm (Length x Width x Bottom Width) for 20kg Chemical Bag.

Loading Capacity: 20kg - 30kg

Ply of Paper: 3 ply of 90g paper + 1 ply of PP film

Reinforcement: Yes

Perforation: Yes

Cutting: step cut

Recommended Machine: ZT9802S TUBER with ServoSystem & HD4916BD BOTTOMER with inside and outside Reinforcement unit

Food Paper Bag Details

Size: normally 60cm x 48cm x 14cm (Length x Width x Bottom Width) for 25kg food bag.

Loading Capacity: 25kg - 50kg

Ply of Paper: 2 ply of 90g paper + 1 ply of PP film

Reinforcement: optional

Perforation: Yes

Cutting: step cut / flat cut

Recommended Machine: ZT9804 TUBER & HD4916B BOTTOMER with inside Reinforcement unit

WHY CHOOSING US

1. Fully Automatic making process

2. Key process controlled by Servosystem

3. Professional technical service for installation, training and maintenance

4. Full solution for factory construction

5. Support free spare parts for replacement

6. No effects to the environment

What we offer is not only machines, but good customer service!

~~ Let's make a better future ~~

Contact us if you need more details on Mutil-Wall Bags Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cement Paper Bags Production Line、Paper Tubes Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Paper Bag Machine > Others Paper Bag Machine

Premium Related Products

Other Products

Hot Products

Automatic Kraft Paper Bag Making MachineValve Paper Bag Tuber Production Line with Printing Machine (ZT9802S & HD4916BD)Full Automatic Kraft Paper Bag Making Machine (ZT9802S & HD4916BD)Newest Automatic Chamical Package MachineHigh-Speed and Fully Automatic Cement Paper Bag Making MachineryFully Automatic Cement Paper Bags Packing MachineryHigh-Quality Cement Bags Making MachineryFully Automatic Pad Machine Glue Bing Notebook Making Machine (LDGNB760)High-Speed Multiwall Paper Bag Making MachineryAutomatic Valve Paper Bags Making Machine PriceAutomatic Pasted Valve (PV) Multiwall Paper Bags Making MachineLd-1020 Fully Automatic Exercise Book Making MachineCheap Fully Automatic 2 Colors Exercise Book Text Books Subject Notebook Making Machine Ld1020School Wire Exercise Book Machineflexography Printing Ruling MachineNote Exercise Book Making Machine Glue MachineHot Melt Glue Adhesive Exercise Book Machine