Automatic Energy Saving Flexo Printing Valve Paper Bag Making Machine

Basic Info

Model No.: ZT9802S, HD4916BD

Product Description

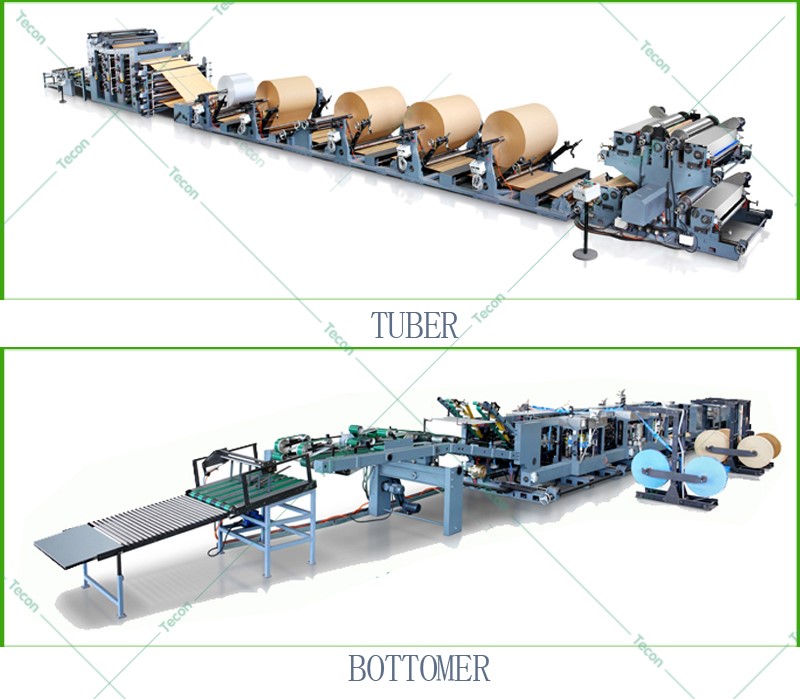

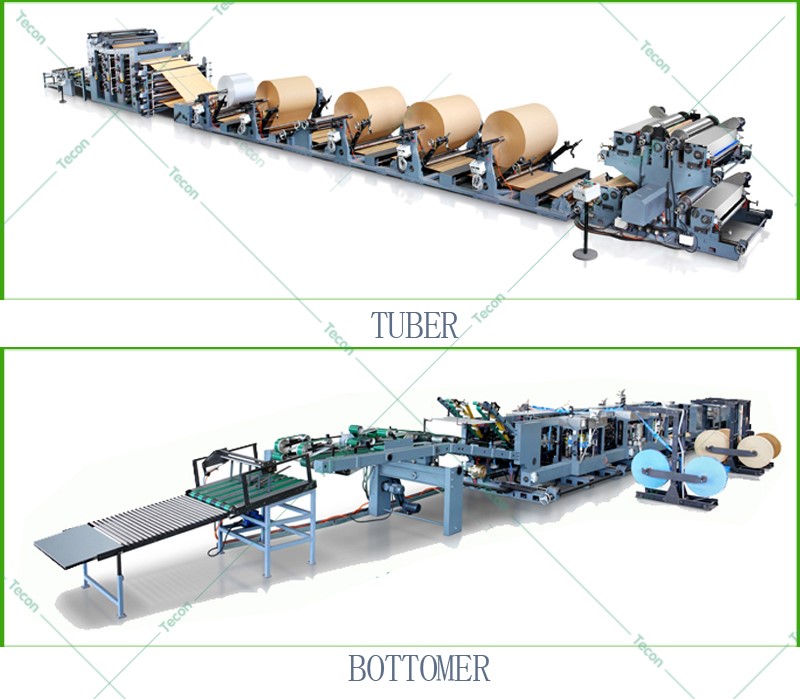

Model NO.: ZT9802S, HD4916BD Lines: 1 Seals Mode: Automatical Sealing Continuous-Rolled: Yes Layer: 1-5 Computerized: Computerized Cutting Unit: Stepped End Cut,Economy/Flash Cut & Notch Cut Trademark: Tecon Origin: Guangdong Foshan Product Line: Cement, Chemical Voltage: 380V Speed: Medium Sealing & Cutting: Glue Sealing and Cut by Tearing off Unit Machine Type: Bag Forming Machine Type: Paper Bag Making Machine Time Required for Bag Size Change: 30min Specification: CE HS Code: 8441200000 Our paper bag production line consists of paper tube forming machine(Tuber) and Bottom Pasting Machine(Bottomer). The products-Valve bags are used for a vast number of applications, primarily in the building materials and food industries, to filling goods such as:cement,chemical material, feeds, fertilizers,tea,rice etc.

Valve paper Bags:

Bags can be made of 2~4 layers kraft paper or paper with one layer of PE/PP film.2~4 colors printing available in Tuber line.

The bags opening or valve in one corner through which the sack is filled. The valve is made with an inner flap which functions as a self-closing check valve after filling. It is available with a plain valve or with an extended inner sleeve of paper or film.

Different models can produce different kinds of bags,like standard cement bags,chemical/cement bags with bottom strengthen sheet,tea bag with PP Liner to enhanced moisture protection.

Machine Technical Parameters:

Product show:

Our advantage:

1.Specialize in design and manufacture valve sack machine for 30 years;

2.CE Certified;

3.Our tuber machine and Bottomer Machine have gained over 50 utility model patents;

4.Longer service life with NSK bearings,SIEMENS control system and high quality gearings.

5.Cost effective compare to W&H,Germany and Newlong,Japan.

Contact us if you need more details on Paper Bag Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Valve Paper Bag Machine、Bottom Pasting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Valve paper Bags:

Bags can be made of 2~4 layers kraft paper or paper with one layer of PE/PP film.2~4 colors printing available in Tuber line.

The bags opening or valve in one corner through which the sack is filled. The valve is made with an inner flap which functions as a self-closing check valve after filling. It is available with a plain valve or with an extended inner sleeve of paper or film.

Different models can produce different kinds of bags,like standard cement bags,chemical/cement bags with bottom strengthen sheet,tea bag with PP Liner to enhanced moisture protection.

Machine Technical Parameters:

| Model | ZT9802S+HD4913BD |

| Tuber Speed: | 130~150 tubes/min |

| Bottomer speed: | 80~130 bags/min |

| Colour printing: | 2 colors available (ZT9804 is 4-color printing) |

| Diameter of print roller: | ø144~ø314 mm |

| Printing width: | 1300 mm(MAX) |

| Number of plies: | 2~4 papers and 1 PP/PE liner obtional. |

| Paper reel width: | 860~1260 mm |

| Paper reel diameter: | Max. 1, 300 mm |

| Paper Bag Width: | 420~600 mm |

| Paper bag Bottom width: | 90~130mm |

| Paper bag Length: | 520~880mm |

| Distance between bottom centers | 420~780mm |

| Size of tuber: | 34.3m*2.4m*2.7m( L*W*H) |

| Size of bottomer: | 21.3m*2.3.m*1.8m ( L*W*H) |

| Air consumption: | 1,100L/min |

| Power consumption: | 63kw(ZT9802S 30KW,HD4913B 33KW) |

| Total weight | 52.7T (30+22.7) |

| Application | Mainly for making cement bags |

Product show:

Our advantage:

1.Specialize in design and manufacture valve sack machine for 30 years;

2.CE Certified;

3.Our tuber machine and Bottomer Machine have gained over 50 utility model patents;

4.Longer service life with NSK bearings,SIEMENS control system and high quality gearings.

5.Cost effective compare to W&H,Germany and Newlong,Japan.

Contact us if you need more details on Paper Bag Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Valve Paper Bag Machine、Bottom Pasting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Tuber Machine

Other Products

Hot Products

Automatic Kraft Paper Bag Making MachineValve Paper Bag Tuber Production Line with Printing Machine (ZT9802S & HD4916BD)Full Automatic Kraft Paper Bag Making Machine (ZT9802S & HD4916BD)Newest Automatic Chamical Package MachineHigh-Speed and Fully Automatic Cement Paper Bag Making MachineryFully Automatic Cement Paper Bags Packing MachineryHigh-Quality Cement Bags Making MachineryFully Automatic Pad Machine Glue Bing Notebook Making Machine (LDGNB760)High-Speed Multiwall Paper Bag Making MachineryAutomatic Valve Paper Bags Making Machine PriceAutomatic Pasted Valve (PV) Multiwall Paper Bags Making MachineLd-1020 Fully Automatic Exercise Book Making MachineCheap Fully Automatic 2 Colors Exercise Book Text Books Subject Notebook Making Machine Ld1020School Wire Exercise Book Machineflexography Printing Ruling MachineNote Exercise Book Making Machine Glue MachineHot Melt Glue Adhesive Exercise Book Machine